|

|

Piezo Plasma technology in 3D printing,Bonding individual parts with significantly improved adhesion In recent years, 3D printing has become increasingly important and is now established as a manufacturing technology in industry |

Piezo Plasma technology in 3D printing

Bonding individual parts with significantly improved adhesion

In recent years, 3D printing has become increasingly important and is now established as a manufacturing technology in both industry and the private sector. Due to its increased importance, the demands on quality, material variety and robustness are now growing accordingly. For years, RP plasma has been researching plasma activation in 3D printing.

A great challenge for Creabis is the 3D printing of large and complex components, To make use of the advantages of 3D printing for larger components, they are printed as individual parts and then bonded together. In practice, predefining joint geometries with maximum bonding area and the gluing itself pose challenges that should not be underestimated. In particular, the strength of the bond is especially critical for long narrow joints where the available bonding surface is minimal.

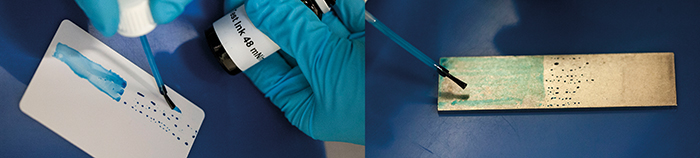

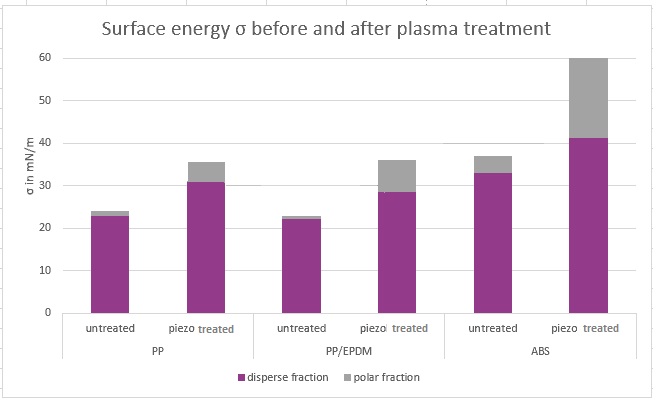

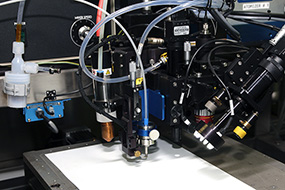

This weakness of 3D printing is in turn the strength of the plasma technology of RP. If a surface is functionalized with plasma before bonding, the resulting bondings show a significant improvement in adhesion. This surface functionalization through plasma treatment is essentially based on two effects: Fine cleaning of the surface from organic contaminants and increasing surface energy for an improved wettability by adhesives. The piezo plasma – an efficient and compact handheld plasma device from RP plasma that requires no special technical knowledge or complex infrastructures – is excellently suited for preparing 3D printing parts for bonding. The core of this handheld plasma device is the piezo plasma generator – a high-voltage discharge device for generating cold atmospheric pressure plasma.

Internal tests reveal that the components treated with plasma technology have an adhesive bond that is three times stronger than that of untreated parts.