|

|

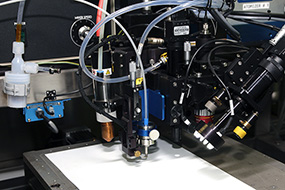

Piezoelectric plasma integration generator |

The small cold-active plasma integration unit.

The compact integration unit is supplied with control cable and power supply ready for use. Operation with industrial compressed air via standardized hose connection. Well thought-out and high-quality: just get started!

The advantages of the PDD-Technology (Piezoelectric Direct Discharge) are obvious: Piezoelectric direct discharge is the more efficient excitation technology with maximum active plasma yield. The cold-active plasma process is compatible with any material. The Piezo generator is optimized for efficiency and user friendliness, complemented by functional nozzle inserts for your application processes. In terms of power consumption, there is no more efficient plasma process for your surface treatment on the market. Cleanly print, securely glue or effectively sterilize.

For stationary mounting or in moving units. The solution for your 24/7 applications in industry and laboratory.

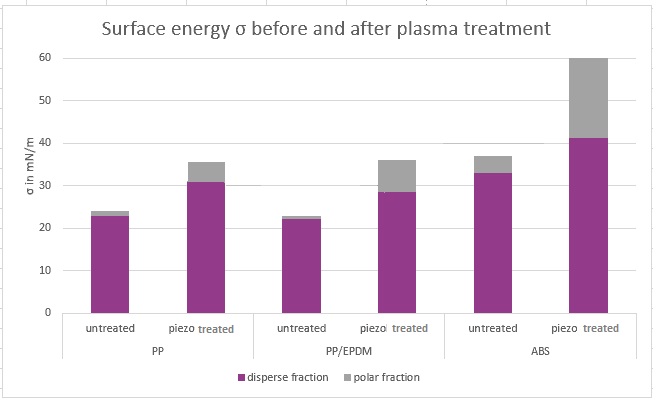

Surface Activation

Laboratory technology, medical technology, precision mechanics, micromechanics, optics, assembly technology, electronics.

Printing and gluing

Inkjet, pad printing, microfilling, wetting behavior of automated processes.

Germ reduction

Microbiology, food and packaging technology, medical technology, microfluid technology.

Technical specifications

- Electrical connection 110 – 240 V / 50 – 60 Hz / 15 V DC

- Power consumption . 30 W

- Weight 180 g

- Plasmatemperature <50 ° C

- Typical treatment distance 2 – 10 mm

- Typical treatment width 5 – 20 mm

- Design integration unit with gas connection

Features

- Operation with compressed air or nitrogen

- Suitable for almost all materials

- Cold plasma

- Easy integration

- Operating safety

- Optimal efficiency

- Trigger via external switching signal

- Variable exchange nozzles: for special materials and geometries.